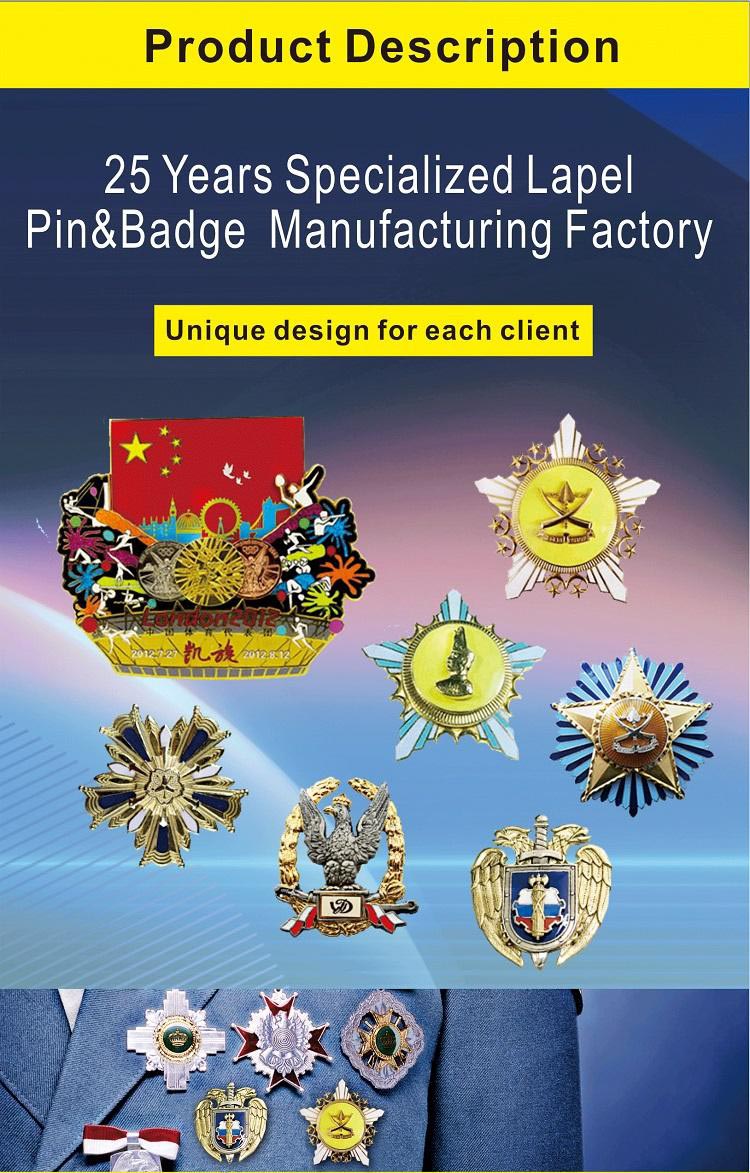

Lapel Pin Custom Supplier – Lapel Pin for Men | KINGTAI – Kingtai

Lapel Pin Custom Supplier – Lapel Pin for Men | KINGTAI – Kingtai Detail:

Making men’s lapel pins

When we make enamel pins, we will use your artwork to make unique molds. It is then stamped into the metal to create a recessed design, which is cut into the shape of the bottom of the pin.The pin seats are plated in gold, silver, bronze or black, and then the grooves are filled with colorful enamel paint, separated by tiny raised walls made from the lines you create during the design phase.

To make a soft enamel pin, apply a layer of enamel paint to the recessed area of the pin. Once dry, the position of the pin is slightly lower than the metal wall of the pin, giving it a ridged finish. Soft enamel pins are a lower production cost option, and ideal if you want to make pins for promotional activities. Although they are resistant to wear, they are not as durable as hard enamels.

In order to make a hard enamel pin, coat the recessed area of the pin with multiple layers of enamel paint. The paint is flush with the raised metal wall, and the surface formed is smooth and flat. The paint is then placed at a high temperature and polished until it is shiny, which gives it a very durable, wear-resistant surface.

Get a Free Sample, Contact Us Now!

Why choose KINGTAI custom enamel pin

Read more news

1. How to make a custom lapel pin

Video

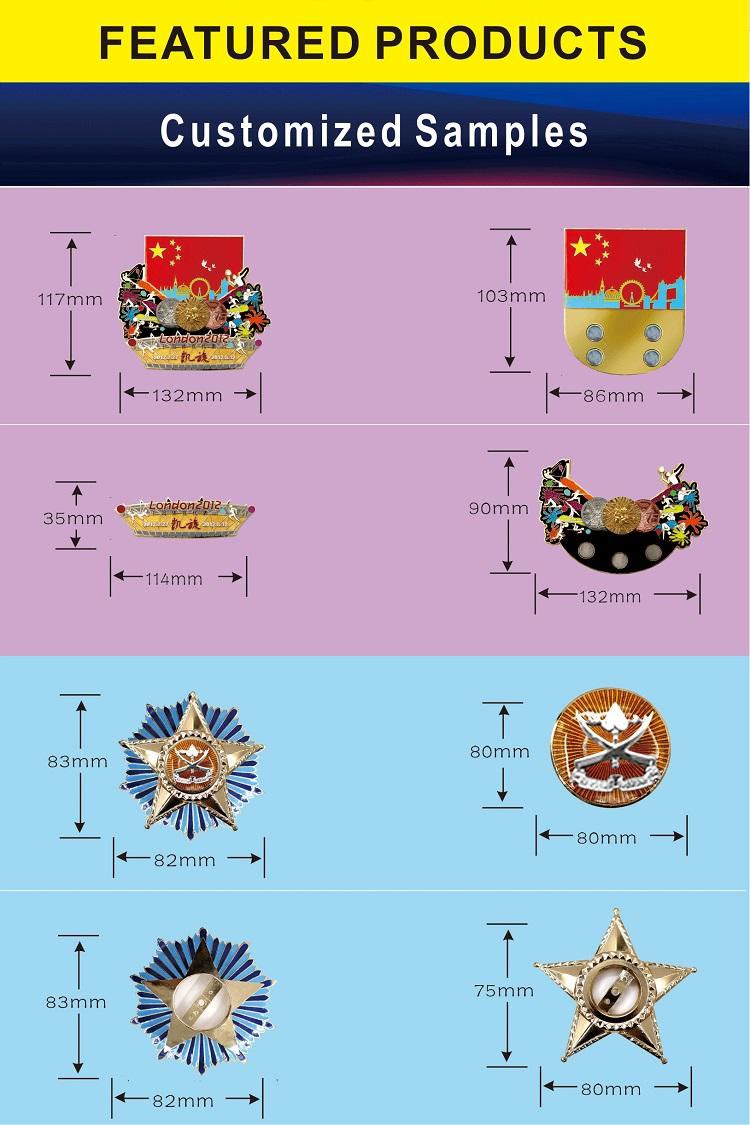

Product detail pictures:

Related Product Guide:

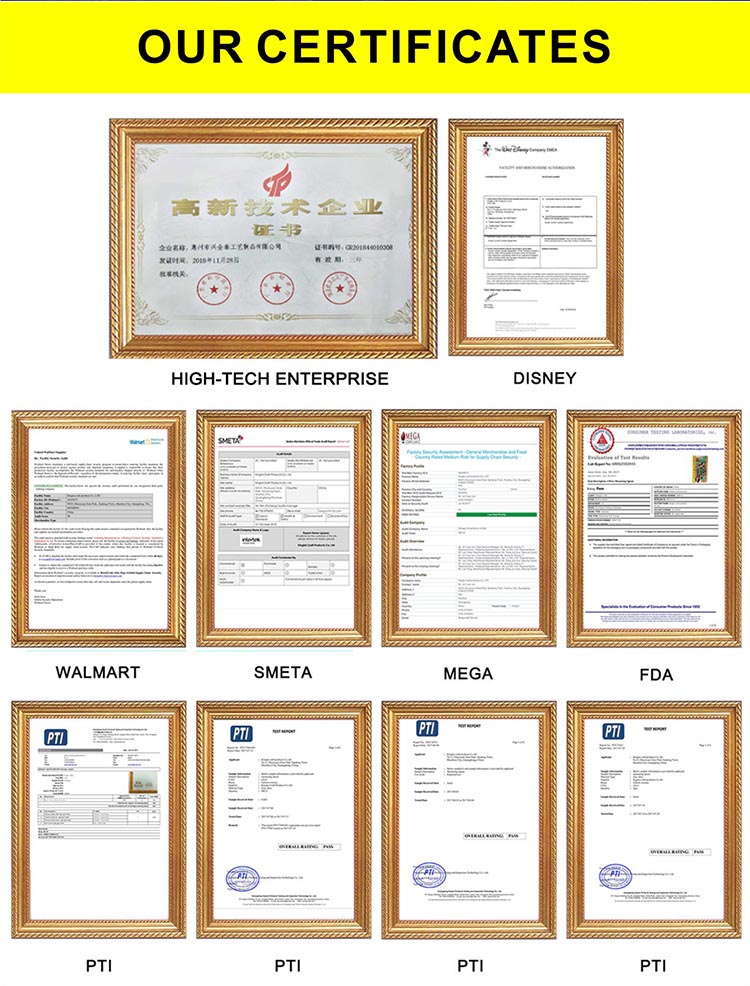

We persistently execute our spirit of ''Innovation bringing growth, Highly-quality making sure subsistence, Administration marketing reward, Credit history attracting clients for Lapel Pin Custom Supplier – Lapel Pin for Men | KINGTAI – Kingtai , The product will supply to all over the world, such as: Paraguay, kazakhstan, Brisbane, The quality of our merchandise is equal to OEM's quality, because our core parts are the same with OEM supplier. The above items have passed professional certification, and we not only can produce OEM-standard items but we also accept Customized Merchandise order.

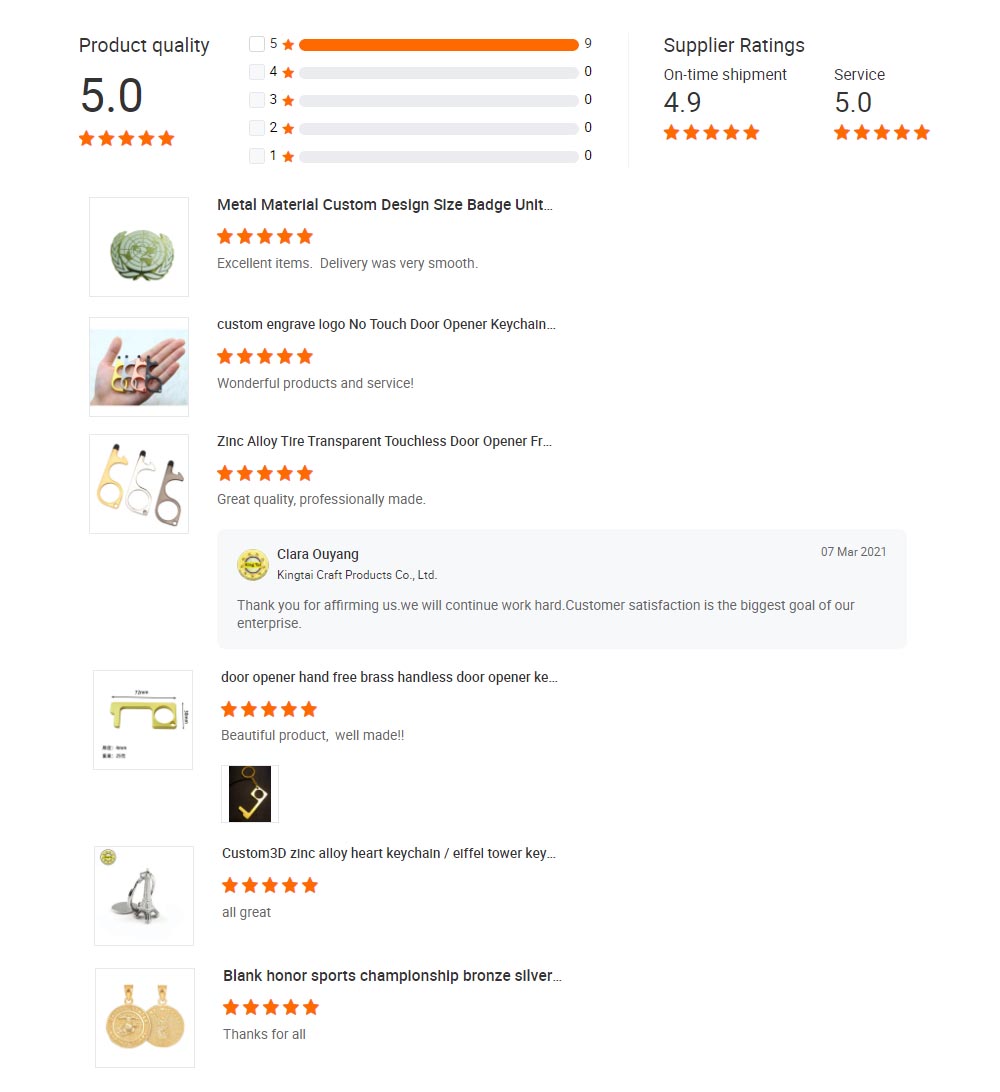

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.