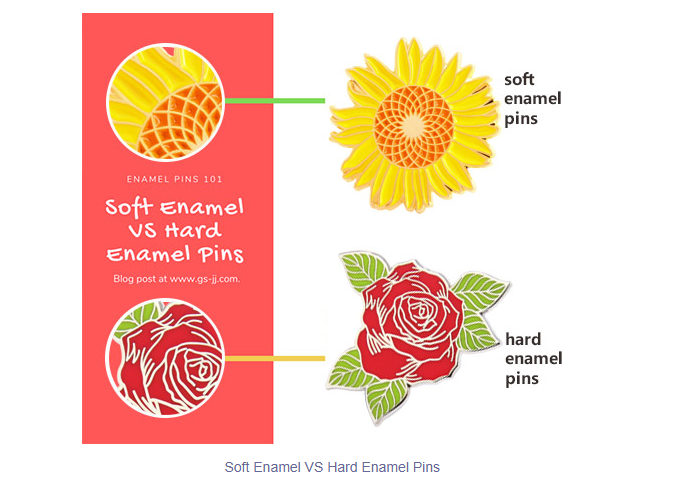

What’s the difference between hard and soft enamel? Soft enamel pins have raised metal edges that give them texture, are less expensive, and offer more design flexibility. Hard enamel pins are smooth and shiny, more durable, and take longer to make.

Creating your first custom enamel pin is fun. But before you get into color choice, artwork, or backer design, you have an important decision to make: soft enamel or hard enamel.

Hard enamel pins and soft enamel pins are two popular types of lapel pins, each with its own unique characteristics. The main differences between the two are in the production process and the final appearance of the pins.

Hard Enamel Pin

Production Process: Hard enamel pins are made by adding multiple layers of enamel to the metal base of the pin. Each layer is then polished to create a smooth, flat surface.

Appearance: The final result is a pin with a smooth, polished finish that is level with the metal borders. The colors are vibrant and have a glass-like appearance.

Durability: Hard enamel pins are more durable and scratch-resistant due to the polishing process, making them suitable for long-term use.

Soft Enamel Pin

Production Process: Soft enamel pins are made by adding enamel to the metal base, which creates recessed areas when the enamel shrinks during the drying process.

Appearance: The final result is a pin with a textured surface, where the metal borders are raised above the enamel. The colors have a slightly more textured and dimensional appearance compared to hard enamel pins.

Durability: Soft enamel pins are less durable than hard enamel pins and may be more prone to scratching due to the textured surface.

Soft and hard enamel pins go through different production processes

The production process for hard and soft enamel pins starts out the same: create a mold from the pin design, then use the mold to punch or form the pin’s plating (the metal base of the pin). After that, their paths to pin perfection diverge, with different steps required for each pin typ

Soft enamel pin construction

Once the plating is ready, there are three steps to completing a soft enamel pin.

1. Electroplating or dying the plating

Electroplating is the process of adding an outer layer of metal, like gold or silver, to the pin’s base of iron or zinc alloy. The plating can also be dyed with a color at this stage.

2. Enameling

The next step is to put liquefied colored enamel in the cavities of the metal base. In soft enamel pins, each cavity is only partially filled. That’s why you can feel the raised metal edges in soft enamel pins.

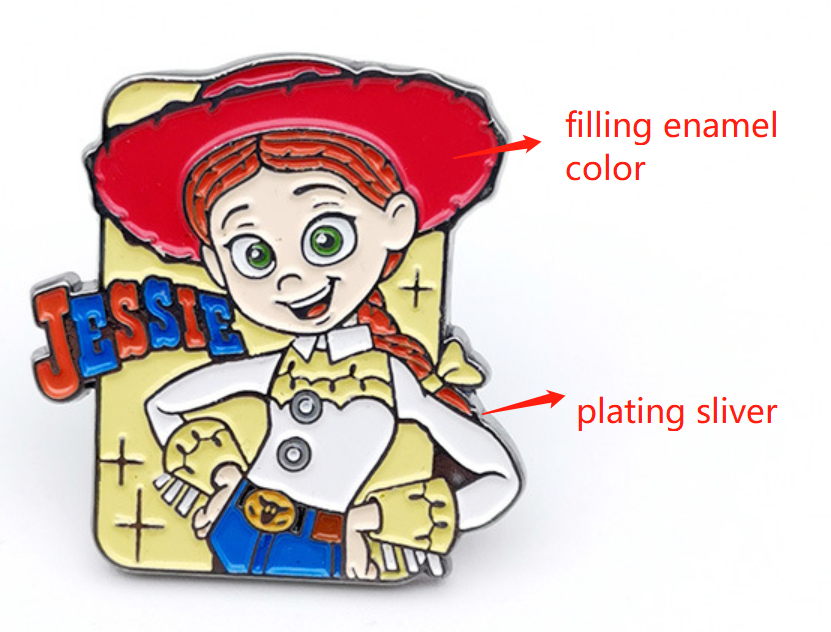

In this example, the silver plating is raised, forming both the outer edge of the pin as well as some of the design elements. The colored enamel is recessed.

3. Baking

Finally, the pin gets placed in an oven and baked to set the enamel.

Hard enamel pin construction

Both the number and order of steps it takes to make a hard enamel pin are different.

1. Enamel filling

Unlike in soft enamel pins, each cavity of a hard enamel pin is overfilled with enamel. Also, note that the enamel filling happens before electroplating in this process.

2. Baking

Hard enamel pins are baked after each color of enamel is added. So if a pin has five unique colors, it will be baked five times.

3. Polishing

The enamel that’s been overfilled and baked gets polished down, so it’s level with the plating. You can still see the metal plating; it’s just smooth so there are no raised edges.

4. Electroplating

The magic of electroplating still allows you to add a thin veneer of metal over the exposed iron or zinc edges of a hard enamel pin. But you’re restricted to only shiny metals like gold or silver.

If you look closely at this funky pin we made, you’ll see the exposed, shiny gold plating. But notice it doesn’t stick out above any of the blue or colored enamel sections.

Soft VS Hard Enamel Pins,which is more durable ?

In summary, hard enamel pins have a smooth, polished finish and are more durable, while soft enamel pins have a textured surface and are slightly less durable. The choice between the two types of pins depends on the desired appearance and the intended use of the pins.

At Kingtai, we offer both soft and hard custom enamel pins for the lowest factory price. Ultimately, the custom pins come down to your personal preference. You could pick the appearance and process that work best for your design.

If you are still unsure, contact us and let us know. As an enamel pin maker with 20 years of professional experience, Kingtai is able to help you to pick out the most suitable one and the best looking one for your design.

About Kingtai Craft Products Co., Ltd.

Kingtai Craft Products Co., Ltd. focus on custom metal craft products for more than 20 Years. We are the OEM maker behind the metal craft products brands. We support our partner metal craft products from the idea to the market. Our manufacturing capabilities include the production of a diverse range of craft products, such as lapel pins, soft enamel pins products, hard enamel pins products, military pins products, metal medals and other custom keychain products as per your requirements. We possess the extensive experience to work with metal craft and can guide you in your decision and all through your development to achieve the execution levels you require.

Post time: Apr-10-2024